|

Life of Mine Planning |

Life of Mine Planning

Life of Mine Plan fundamental questions are:

-

What are the optimal limits to mining the mineral deposit?

-

How to mine the deposit within the optimal limits to meet all economic, technical and environmental requirements?

-

What are the risks associated with any potential Life of Mine Plan?

The relative importance of these questions and the answers depend on the nature and characteristics of the deposit. Is the plan aimed at maximizing NPV or at blending materials to given specifications? Is the deposit large and complex or not so large and easy to mine?

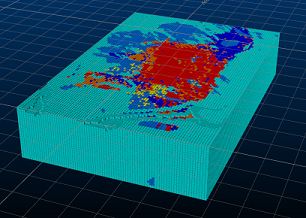

Your product provides all tools necessary to develop Life of Mine Plans for most deposits. Planning with Studio NPVS involves the following steps:

-

Import a Geological Block Model.

-

Define economic parameters (product prices, mining costs, processing methods with costs and recoveries, etc.) and build the Economic Model.

-

Find the optimal limit to mining and the first block by block extraction, that follows either NPV maximization logic or material blending logic with the Pit Optimizer. †

-

Define pushback specifications and generate a sequence of practical pushbacks with the Pushback Generator.

-

Set annual production targets and find year-by-year mining schedule with the Scheduler.

-

Refine the annual schedule with Material Allocation Optimizer (MAO) or Mine Flow Optimizer (MFO). ‡

† Planning with Studio Maxipit ends here.

‡ Planning with Studio NPVS ends here.

Geological Risk Assessment (GRA) functions allow you to estimate probability distribution parameters of any optimization outcome. It also offers an alternative to define the limits to mining using the concept of Risk Rated Pits. GRA requires importing conditional simulation results from an external application.

Planning to Maximize NPV

The Net Present Value (NPV) of a deposit is defined as a sum of time discounted revenues from blocks mined less similarly discounted mining and processing costs. To calculate NPV we need to know:

-

which block to mine (the mining limits)

-

when a block will be mined (time distribution of mining costs)

-

when a block will be processed (time distribution of processing costs).

If NPV maximization is the goal:

-

For pit optimization select Lerchs-Grossmann ultimate pit and NPV maximizing extraction sequence options. The NPV is calculated assuming time flow proportional to ore tonnage mined and processing costs incurred at the same time as the mining costs.

-

Generate pushbacks with the NPV maximizing extraction sequence as input. The pushbacks are optimized to deliver the highest NPV while mining the pit in practically acceptable stages.

-

Find a practical mining schedule with the Scheduler. The resulting NPV estimate reflects more closely the NPV obtainable within practical mining constraints.

-

Reevaluate NPV with MAO or improve it with MFO. Both programs distinguish between time distributions of mining and processing costs.

-

Run conditional simulation in your general mining package and find out with GRA how reliable the NPV estimates really are.

Planning to Optimize Blending

-

For pit optimization select either Lerchs-Grossmann ultimate pit or Maximum Resource pit option. Choose to generate a blended extraction sequence.

-

Generate pushbacks.

-

Set scheduling targets to include the blending and other requirements, and run the Scheduler.

-

In some cases fulfilling all blending and quality requirements is impossible without stockpiles and/or external material resources. If so, run MAO.

|

|

Related Topics |

|

|

Pit Optimization

Essentials |

Copyright © Datamine Corporate Limited

JMN 20065_01_EN